CNC Machining in Portland - Form Factory: Quality CNC Machined Parts and Prototypes since 2004.

form factory

What sets us apart?

At Form Factory, we are the ones actually making your stuff!

PERSONAL

All of our machined parts and prototypes are produced right here in Portland, Oregon, in our own internal Model Shop. We can ensure our quality and consistency, and your projects confidentiality, because we never sub-contract our projects out to another company. We do all of our own CNC programming, machining, and operation, as well as any finishing, painting and final assembly right here at Form Factory. Any CAD development to add functionality or facilitate machining is also done exclusively on-site.

LOCAL

We work only with local vendors for any further processing such as anodizing, powder-coating, or laser etching. Any outsourced post-processing always ships back to our shop for final inspection and approval prior to shipping to our clients. We partner only with trusted, reliable vendors.

Being local also means the Project Manager, Mechanical Engineer, or Industrial Designer adding their expertise can easily check in with us in person during the fabrication process. This may be needed to add internal components or hardware. It can also be helpful to review a form, fit, finish or function midstream. We welcome this interaction as it helps make certain our progress is headed toward the objective even before completion.

QUALITY

At Form Factory, quality runs through each step of a project. From getting the details right on the initial estimate, through creation of the parts, to ultimately shipping an order. We inspect all parts upon completion, and then neatly pack them for safe shipment, with the parts clearly labeled and listed. Sometimes timeframes are so tight we are shipping straight to the board room. Our packaging makes opening the box for any final assembly or presentations simple and worry-free.

COMPETETIVE

Some of our competitors have sales offices far removed from where the parts are actually being made. Instead, the work is brokered to a distant location in order to increase the profit margin. This makes communication between the client and the shop actually making the parts slow and cumbersome. This approach also tends to spread intellectual property broadly, even when just getting a cost estimate. Choosing to work with one of these brokers means you may receive vastly inconsistent quality, even for repeat orders. The parts provided are often sent out to the lowest bidder or first available shop, and produced by a different shop, person, and machine each time you place an order. Parts are then packed and shipped in a different manner as well. This makes consistency almost impossible, resolving problems difficult, and preventing a problem from recurring even more challenging. Over time, the reason for the cost savings you may find when working with these firms becomes self evident.

When you work with Form Factory, you gain the consistency, craftsmanship and expertise your project deserves by working directly with the people creating your parts. We keep your project local, internal, and confidential.

CREATIVE

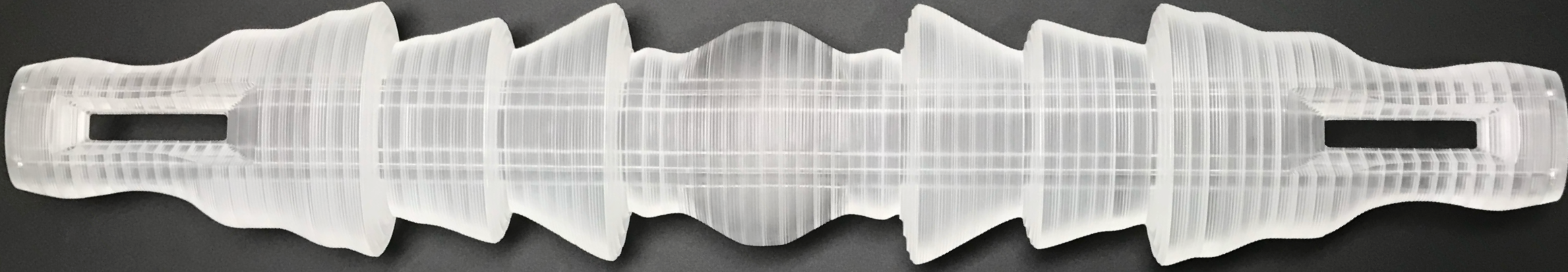

Making something new for the first time can involve many decisions to find the best method for prototyping an idea. With over 30 years of experience in machining and prototyping, we can offer insights that may simplify a detail, reduce cost, or flag potential problem areas. Sometimes small adjustments to the strategy or form can help increase strength, improve cosmetics, or reduce costly lead-time. Because we handle everything from sales to creation collectively, we can be much more responsive than our competition when it comes to any questions or updates that may need handled along the way. This adds value, saves time, and may even improve on the original design. For repeat production orders, parts get better each time as we gain more experience making them.

You may need a prototype for a proof of concept, to test a theory, or answer a question. Or, you might be putting together a presentation to help generate funding. In any case, you never get a second chance to make a first impression. We have the experience to ask the right questions and get the details right the first time, and always meet the deadline. This is why we are the first choice when it comes to machining and prototyping in Portland.

PARTNER

Investing in a prototype provides invaluable feedback you can only get from reality. Partnering with the right team can make all the difference, as often several prototype iterations are needed to achieve optimum performance of your product. The early findings gained from a smart prototyping process can save valuable time and significant future production costs. We can help you move forward with the successful evolution of your next project.

Accelerate your product development. Prototype early. Prototype often.

All content copyright Form Factory 2024